Yes. We can translate your design into a manufacturable product. The earlier we can be involved in your product development the better. We work with you to define the product concept, investigate the manufacturing feasibility and propose the best combination of raw materials to meet your requirements, whether for mass production or batch manufacturing. We support you from the very beginning and help you through the entire concept process, to ensure your product is manufactured to the best quality.

Medical Part Design & Product Development

Expertise in Complex Product Design

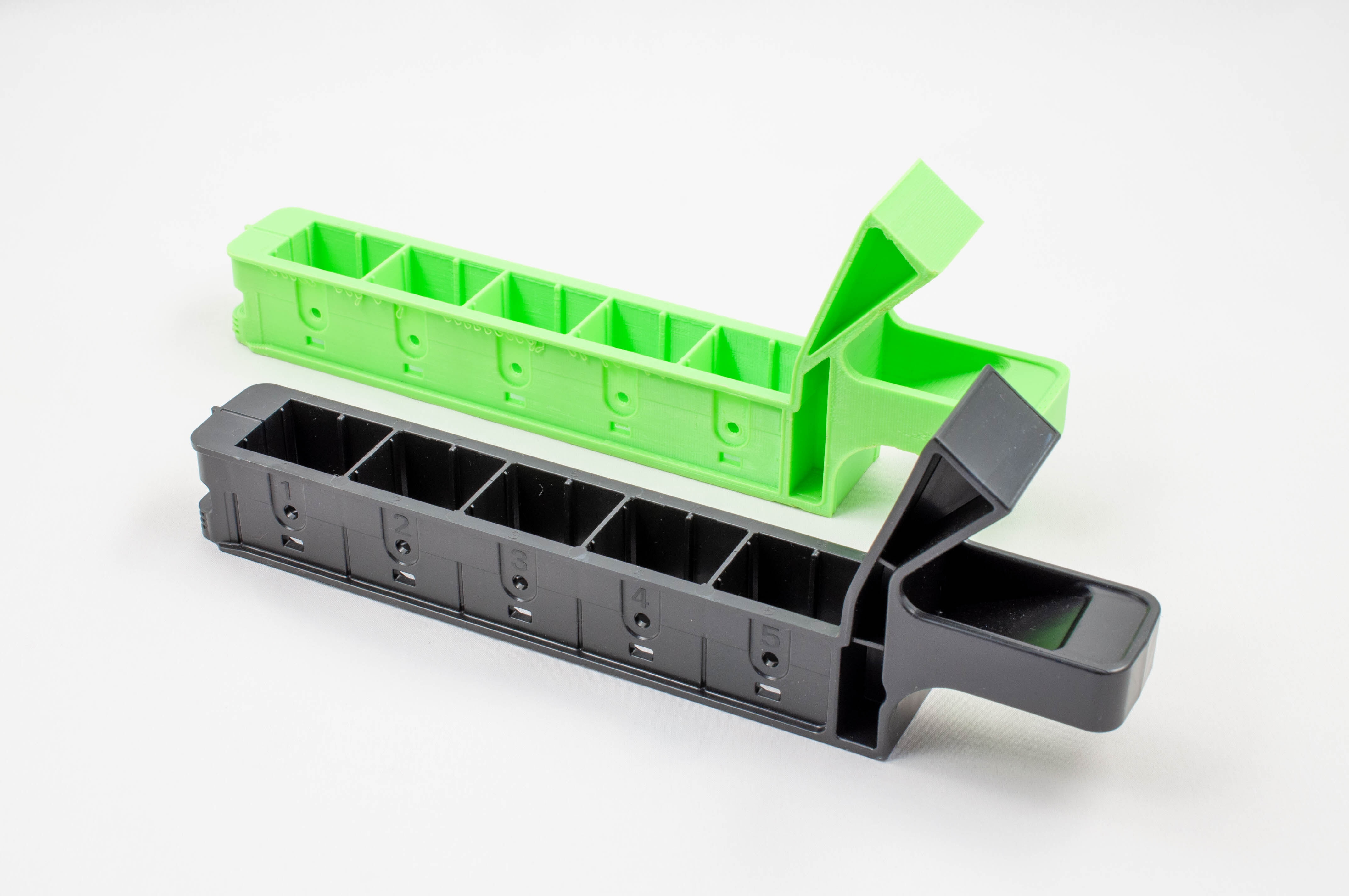

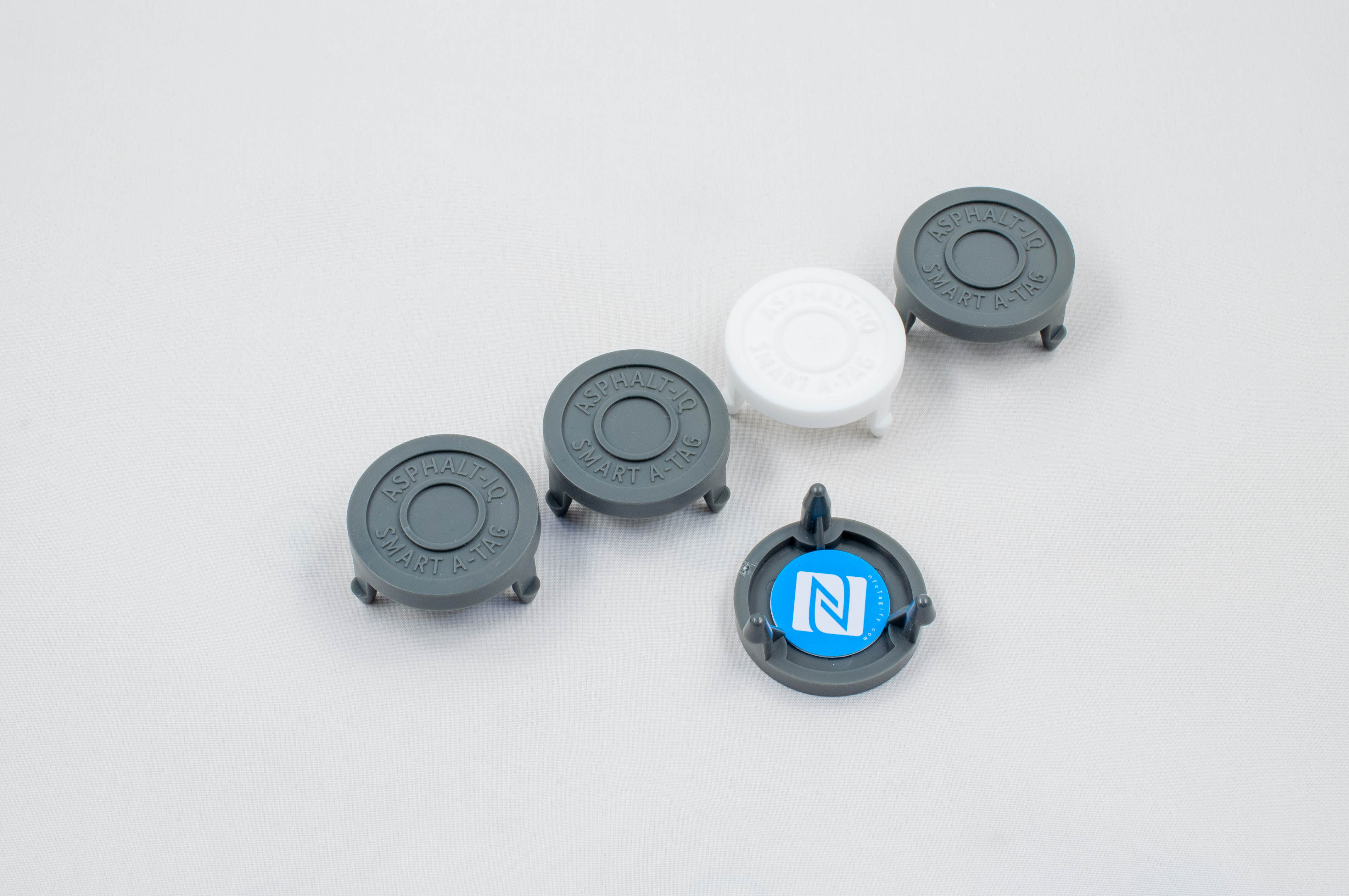

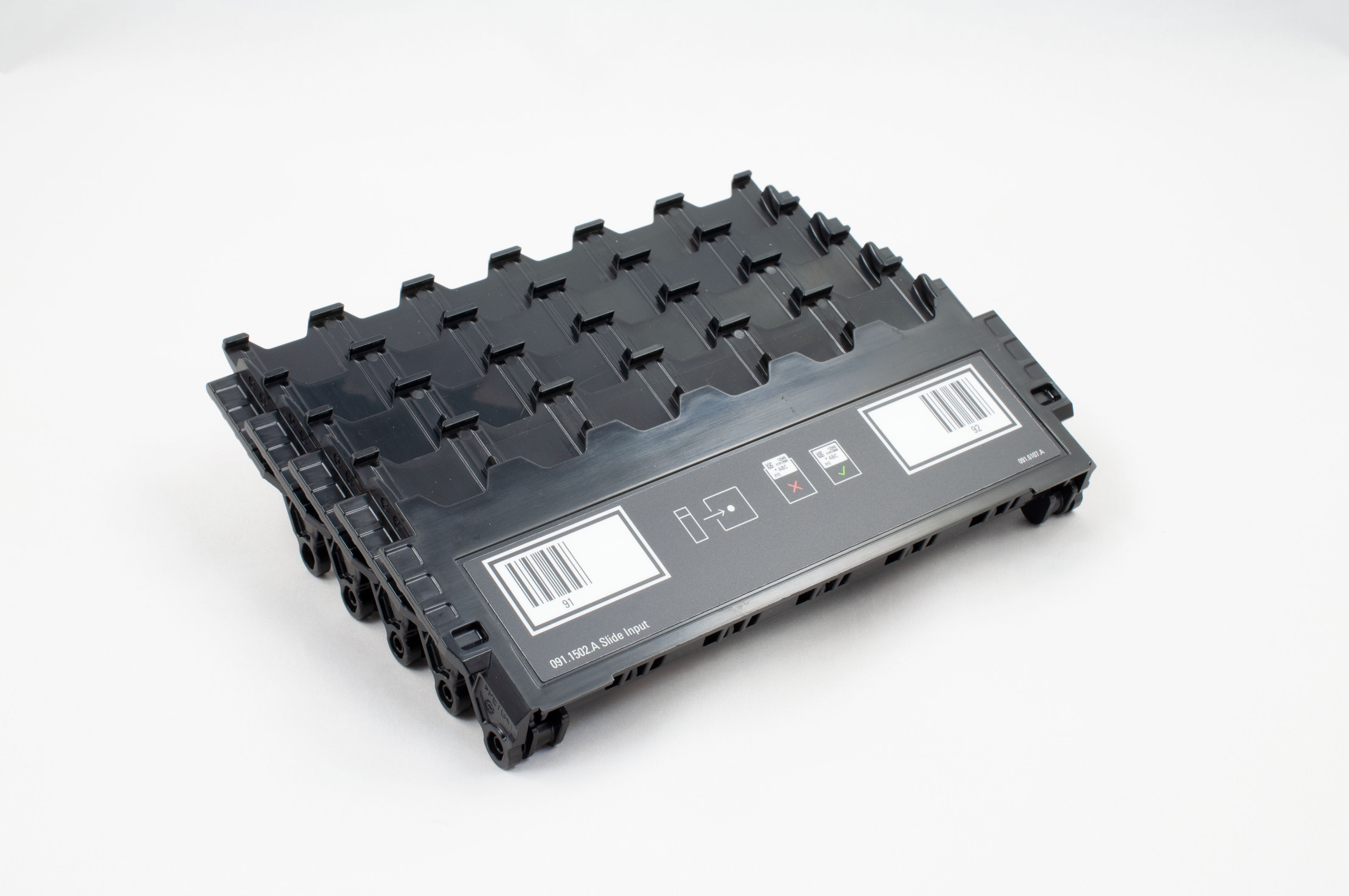

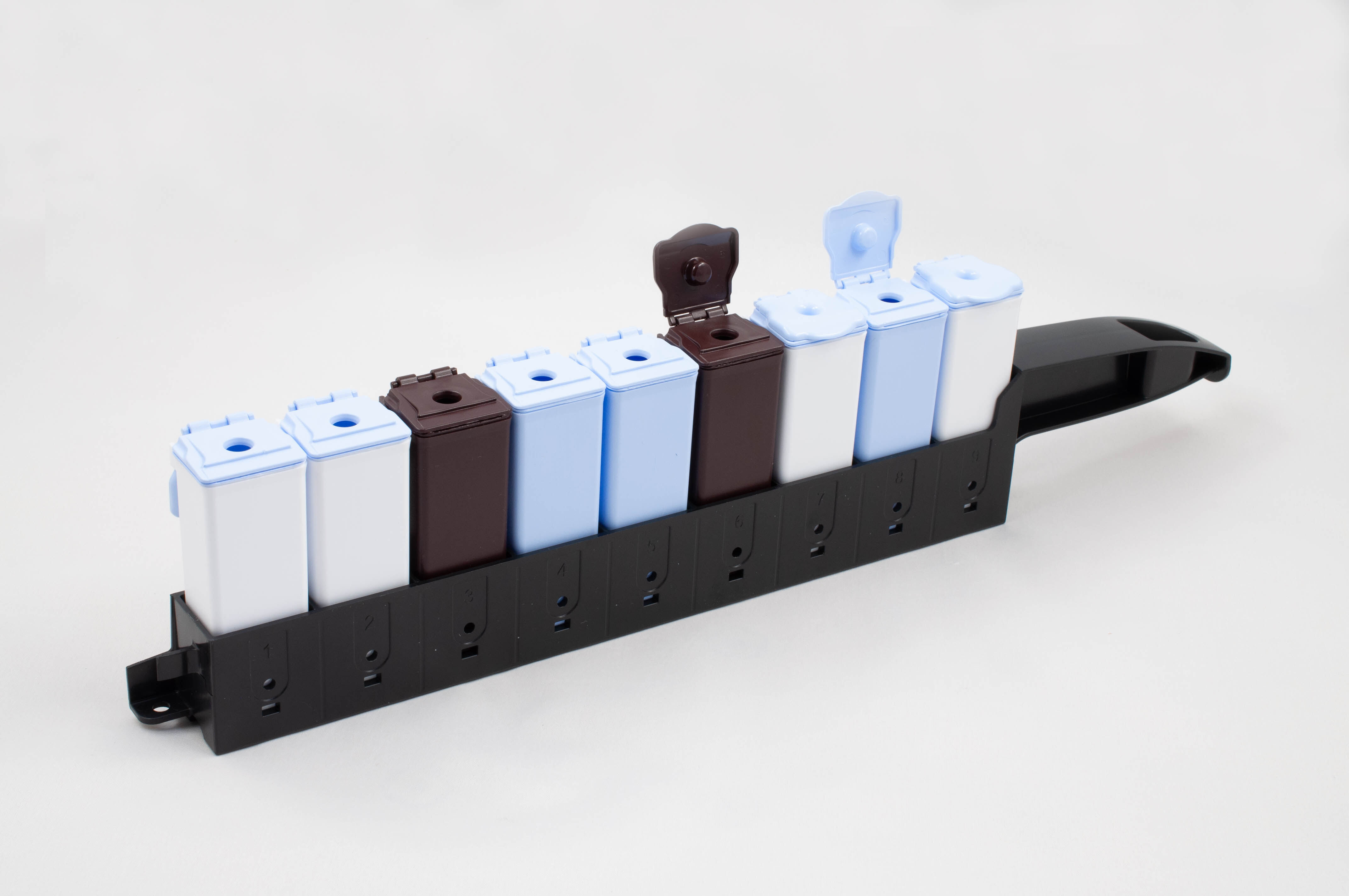

We offer a wealth of expertise in the production of complex, high-precision products as well as simple components. Our proven ‘art to part’ medical device design and development process sees us develop your product from an idea right through to manufacture and delivery. At the heart of this process, is the drive to achieve the highest standard and provide exceptional customer service at every stage. Discuss your next medical plastic project with us at Forme Technologies and discover how we could help you to make it a reality.

Flexible medical product development

Flexibility and agility are key requirements in the medical plastic device manufacturing process. From the advanced Forme Technologies facilities, our team of highly trained staff will work closely with members of your organisation to ensure all activities align closely to your objectives. Whether we’re contracted for low-volume or full-scale manufacturing, we ensure that all efforts undertaken are responsive to changing factors within the industry and the broader market.

Environmentally Focussed

medical product design

Utilising a wide range of materials

Here at Forme Technologies, we understand the best result is the product of careful planning and attention to detail. As such, we take the process of selecting the most appropriate material for each project seriously. We utilise a wide range of commodity-grade and specially imported materials. We have the facility to mould some of the most difficult and sophisticated engineering polymers daily with minimal scrap rates. We recognise that human safety is central to medical product development. To this end, we conform to the numerous standards associated with medical device design and manufacture. We are highly experienced with these requirements and also cater to GMP requirements associated with a number of medical classifications.

Materials we use for Product Design

NEW PRODUCT DEVELOPMENT SERVICES

Enquire about custom medical product design

Forme Technologies is a company with over two decades of experience in plastic product development. We are proud to deliver a full spectrum of manufacturing services, providing cutting edge design and intelligent product development capabilities. You can see some of the products we’ve developed in our Portfolio.

Melbourne Based Global reach

FAQ's

Can you help me develop my idea into a manufacturable product?

How can Forme Technologies assist with the prototyping of my product?

Forme Technologies has extensive experience in the design and development of products for a wide range of industries, including medical, defence and consumer electronics. Leveraging our considerable expertise allows you to potentially realise significant cost savings while achieving a faster time-to-market.

Additionally, we have an in-depth knowledge of environmental requirements such as recyclability, flammability, and UV sensitivity, ensuring that your product meets or exceeds or all required environmental regulations.

How do local and international customers rate your quality and delivery standards?

Forme Technologies is ranked in the top percentile for quality and delivery standards with local and international customers.

What are the expected turn-around times for a new prototype?

As each project undertaken by Forme Technologies is unique, delivery times will vary depending on design, material availability and other factors. Choosing to work with our team ensures that external factors have minimal effect on the delivery of your product. Strong relationships with our suppliers and a deep knowledge of technical aspects of our job allow us to accurately forecast delivery times. Speak to our team to learn more.

What is 'art to part'?

This refers to the process we undertake to develop your product from an idea or concept right through to manufacturing and delivery. At the heart of this process, is an ethos of achieving the highest standard and providing exceptional customer service at every stage of the project.

What is resolved at concept development stage?

The main goal is to ensure that the product can be designed, manufactured and delivered based on your technical and commercial requirements and specifications.

What is the initial cost for developing my concept?

Each project is tailored to your unique requirements. Please get in touch and we can organise a custom quote.

What is your expertise?

We manufacture plastic products/parts/components for the medical, electronic and automotive industry. We specialise in the production of complex, high-precision products as well as the production of simple components. Each product is tailored to your unique requirements. We can discuss potential ways of reducing product costs and time to market. We also offer packaging, storage and delivery solution.