We are committed to reducing our environmental impact and making ongoing improvements in the way we run our business. More than half our operation is now powered by solar energy and conditioned by a new power factor correction system.

Modern Manufacturing

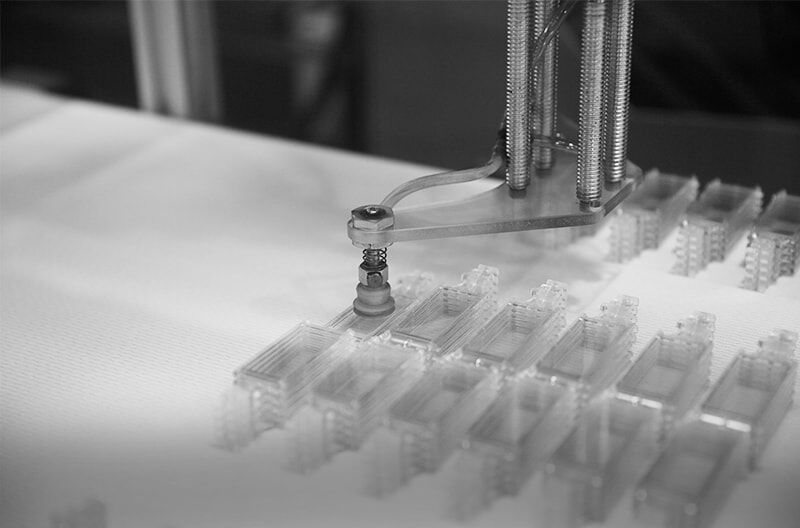

Modern Product Manufacturing Process

Our manufacturing processes are mostly injection moulding and associated processes. We currently operate machines ranging from 35 to 450 tonnes. In order to stay abreast of injection mouldings constantly emerging technologies, our most recent machine additions have been all electric, state of the art machines with every bell and whistle imaginable.

Quality Control

Sophisticated Engineering

Forme Technologies are well versed with the concepts of scientific moulding as well as the associated statistical work that goes into understanding a good moulding outcome. We can also perform designed experiments and various in-depth process analyses such as SPC analysis.

We're experience in moulding some of the most difficult and sophisticated engineering polymers on a daily basis with minimal scrap rates.

One of Australia’s leading plastic products manufacturers, Forme Technologies has a wealth of knowledge on moulding for electroplated applications. This involves new materials and an even greater level of part scrutiny and control.

Based in Melbourne, our plastic manufacturers work according to programmed production schedules, which are often linked to customer Kanban requirements in Australia and overseas.

Speak to Australia’s leading plastics manufacturers

Discuss your requirements with the team at Forme Technologies and discover why firms across Melbourne and around Australia and Globally trust us to help them achieve their business goals.

Call us directly on +61 3 9782 3033 to learn more. Or click on the Get in Touch button to send us your enquiry.

FAQ's

Are you environmentally friendly business, are you green?

Do you support low volume manufacturing?

Yes, we support both high and low volume manufacturing.

What are the costs involved in a manufacturing projects?

The cost of manufacturing will depend on the complexity of the project. We go to great lengths to specify and cost manufacturing according to customer budgets and to maximise the product yields and net return on investments.

What is Plastic Injection Moulding?

Plastic Injection Moulding is the manufacturing process we use to mass produce complex or simple plastic parts. Heated plastic is pressured into a mould to form different parts and products. The process requires a moulding machine where plastic granules are poured into a hopper and are then heated through the machine and injected into a pressured mould, often called a tool. For over 20 years, we have earned an excellent reputation in comprehensive plastic injection moulding services.

What is your Quality Assurance?

We have built an excellent reputation for achieving superb quality on every project, no matter how unique, unusual, or complex. We are ranked in the top percentile for quality and delivery standards with our local and international customers. We are both ISO 9001 and ISO 13485 accredited business.

What plastic materials do you use?

Most products we develop require a high level of engineering input, which means we specify the best engineering materials available. We work with commodity plastics and exotically engineered materials. Some materials are unique to us in Australia. We regularly use and specify materials that are either UL compliant or conform to the ISO 10993 certification for medical and food applications. The materials we use include:

PI – polyimide

PEI – polyetherimide

PEEK – polyetheretherketone

PSU – polysulphone

PC – polycarbonate

PPO – polyphenyleneoxide

PET-G – polyethylene terephalate (glycol modified)

PMMA – polymethylmethacrylate (acrylic)

POM – polyoxymethylene (acetal)

ABS – acrylonitrile butadiene styrene

PC-ABS – polycarbonate and acrylonitrile butadiene styrene

PP – polypropylene

PE – polyethylene

What type of accreditation do you have as a business?

We are an ISO 9001 and ISO 13485 accredited business. ISO 13485 is the standard required for the manufacturing of medical devices.