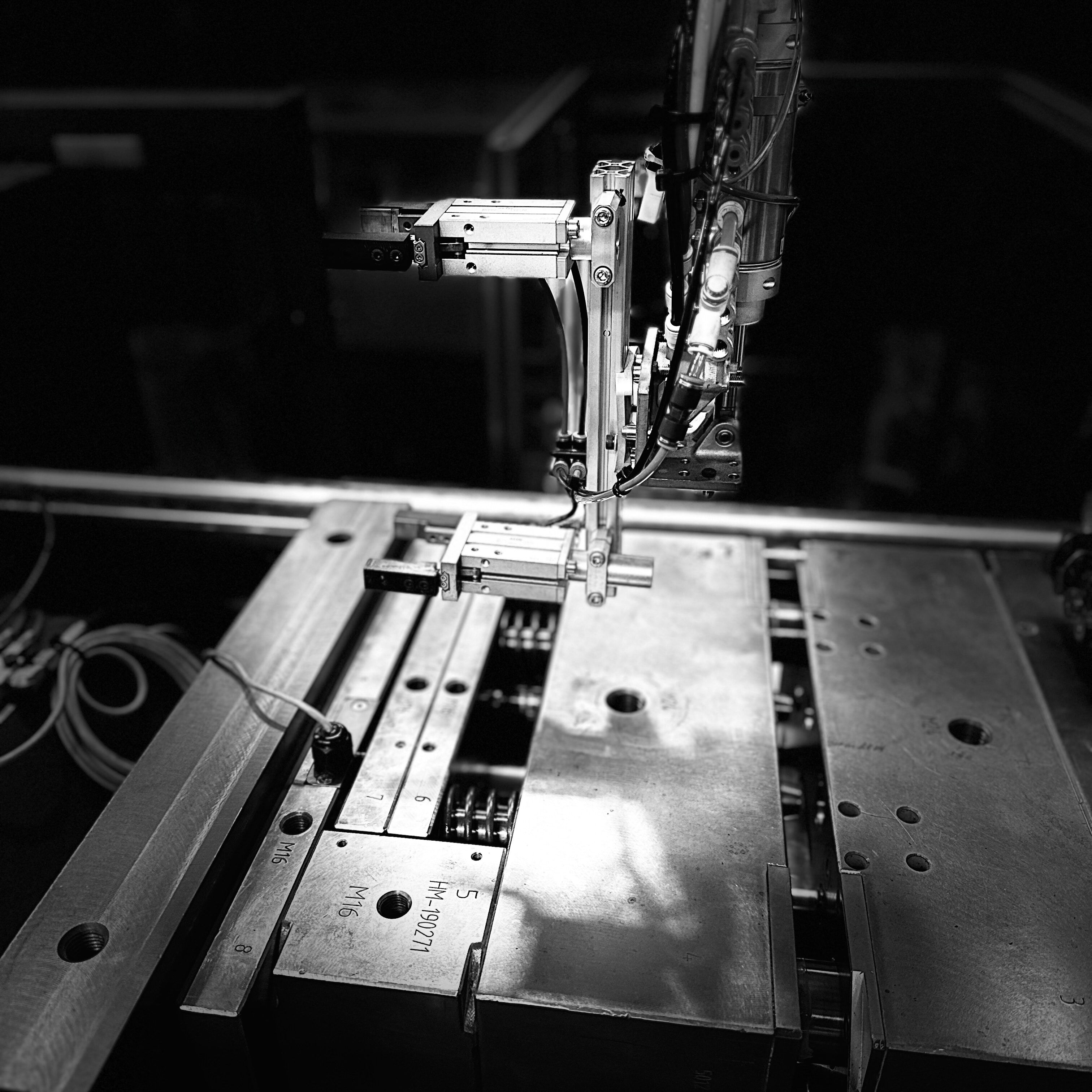

Determining the tooling costs is a complex process that depends on many factors like the size of your part, the number of cavities on the tool to better suit your demand, the timeframe for the project, the injection technology used in your part, the surface finish, features i.e. undercuts, threads, clips, etc. on the design, and any other specifications that need to be met for your part.

Our commitment with our customers is finding solutions that best fit their projects’ budget, timeframe, specifications, and that delivers the best return in their investment.